The analysis of alternatives takes a circle economy to describe as a closed-loop accounting of the utilization of a resource. It is a series of life cycle costs over time. Understanding these costs leads to the proper accounting for operations and utilization of productive resources as a closed loop system.

The circle economy methods are part of measuring industrial ecology.

We understand the closed loop analysis practices for the true life cycle of a system of resources. We can perform the neessary studies and analysis required to properly account for resourde utilisation. This activity usually involves a series of co-ordinated plans.

We work with you to develop these key plans to achieve operational outcomes with the best allocation of resources.

Life Cycle Cost or Analysis of Alternatives (AoA) is a rational and comparative estimate of the total cost of buying, owning and disposing (acquisition and sustainment) of productive plant and equipment. The cost is estimated over the life cycle phases of the product (idea to recycle). The type of phases is usually described by the product type and the industry. Also, the cost elements will change in priority over time as well. An important aspect of a life cycle cost assessment is to assess the impact of a decision. The action to reduce costs in one situation, may adversely impact cost in other aspects. What seemed like a good idea at the time is found later to be a terrible idea. A thorough and objective life cycle assessment will generally expose these weaknesses.

The main issue to consider in life cycle cost is to ensure that it is approached objectively and rigorously. It can help show that the planned course of action leads to a good solution; as well as show that it is not the best value option to achieve productivity goals. If you are currently dealing with problems such as unplanned high maintenance costs, obsolescence, shortage of support resources, and ageing equipment; that could be because a number of years ago an analyst was unable to foresee these events. Or, what is also known to happen is the foreseeable events of the analyst were ignored. The product provides skills in the necessary ability to assess or review future issues as well as short term issues for “no surprises” cost estimates of through life productivity decisions.

For information about this service please email Adrian Stephan to request information.

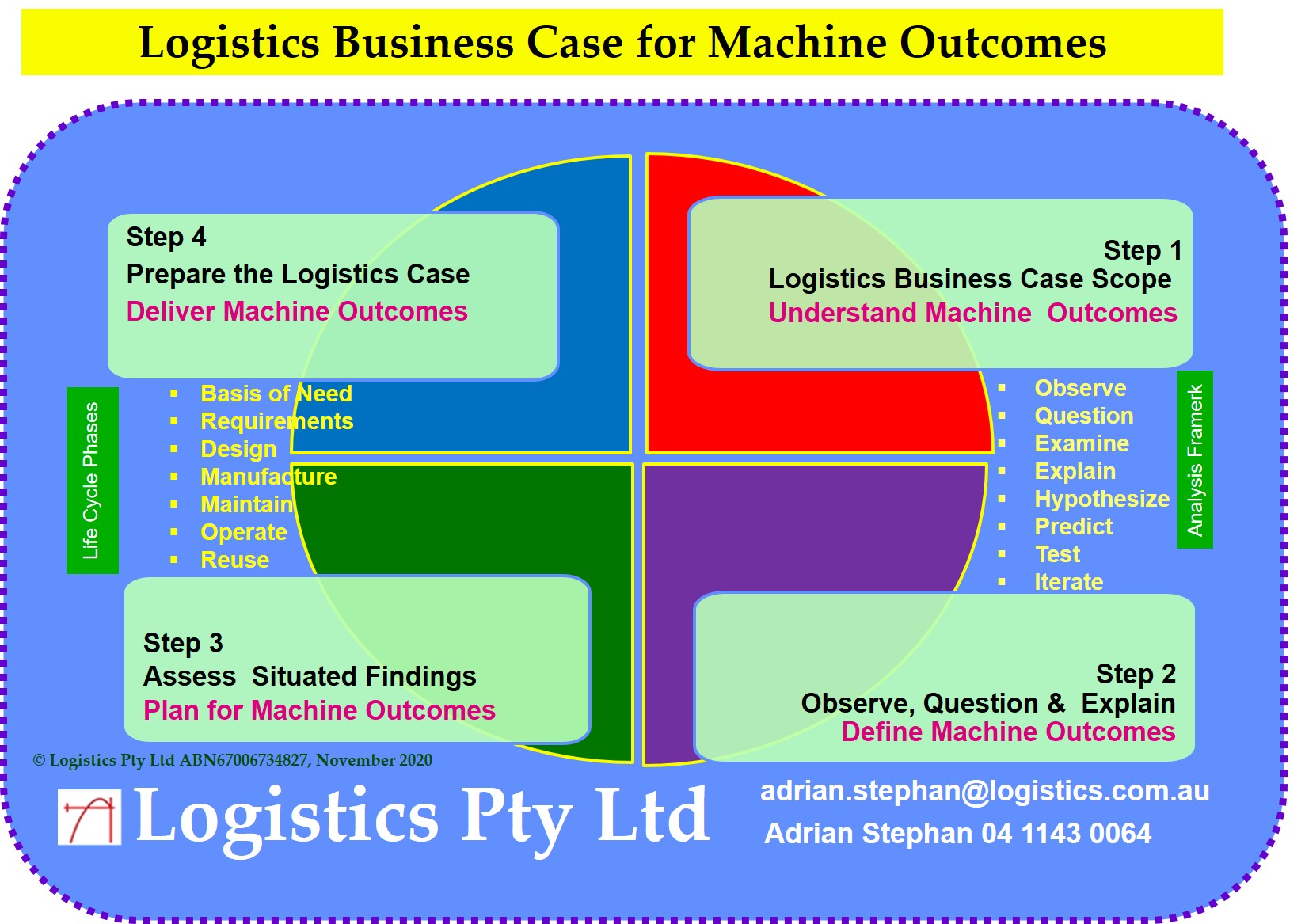

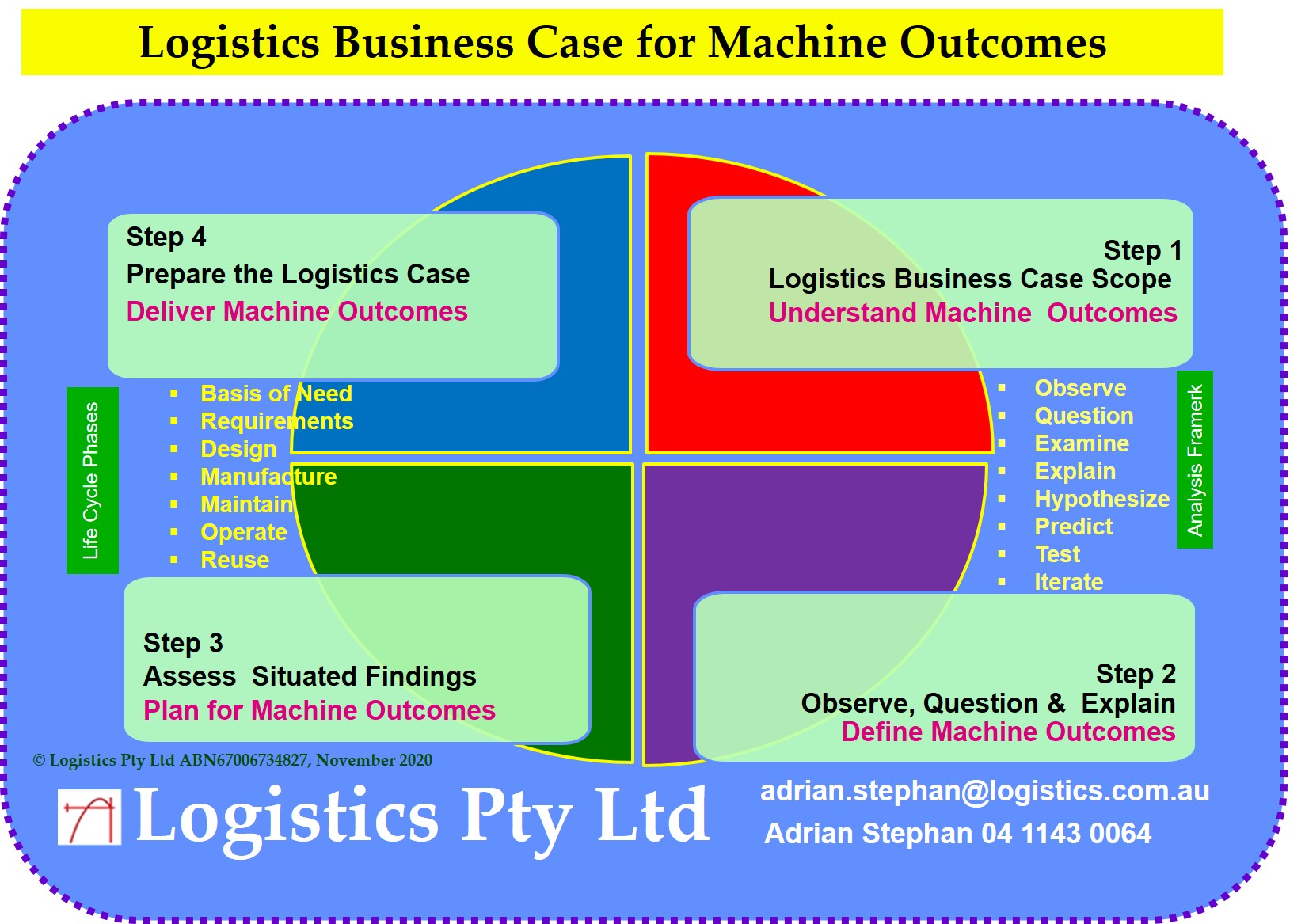

The closed loop plan shows the practice of developing the logistics case for a machine support system. The diagrams show the thinking required for the process.

|